3D Printers: 6 Terms to Know

Experts and newbies alike are routinely confused by a daunting array of duplicative, overlapping and conflicting terms used to describe 3D printer technologies that are essentially the same but are called different things in different environments.

A variety of organizations are advocating the adoption of standardized terms and clear descriptions that distinguish one technology from another. The goal is to reduce confusion, enhance communication, facilitate decision making and clarify 3D printing – which is sometimes called rapid prototyping, additive manufacturing, additive fabrication or desktop manufacturing.

The list is constantly expanding as new technologies emerge, but most can be classified according to the predominant technologies used to process substances and create 3D objects. The primary categories include:

Binder jetting. This process deposits or sprays liquid glues or bonding agents that fuse powdered materials into a solid mass. Technologies include binder jetting and inkjet powder printing.

Directed energy deposition. This process uses a focused heat source produced by laser, electron beam or plasma arc to melt and fuse materials as they are deposited onto the printing bed. Technologies in this category include electron beam melting (EBM), electron beam direct manufacturing (EBDM), ion fusion formation (IFF) and laser powder forming (LPF).

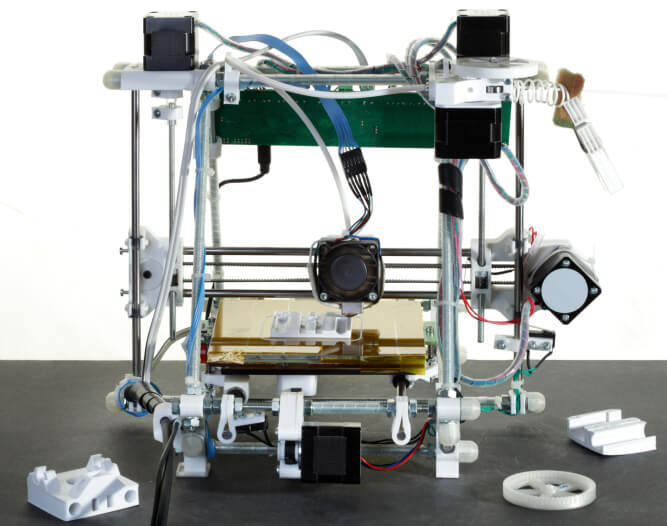

Material extrusion. This process utilizes various types of specialty nozzles to deposit liquid or semi-liquid materials to build an object. Technologies include fused deposition modeling (FDM), fused filament fabrication (FFF), fused filament method (FFM), plastic jet printing (PJP) and thermoplastic extrusion.

Powder bed fusion. This process selectively applies thermal energy to fuse powders deposited onto the printer bed surface. Technologies include direct metal laser sintering (DMLS), electron beam melting (EBM), selective heat sintering (SHS), selective laser melting (SLM) and selective laser sintering (SLS).

Sheet lamination. This process creates objects by stacking and fusing layers of sheet-based materials. Technologies include laminated object manufacturing (LOM) and ultrasonic additive manufacturing (UAM).

Vat photopolymerization. This process is sometimes referred to as light photopolymerization because it forms objects by selectively projecting light onto the surface of photo-reactive liquid polymers held in a vat. Technologies include digital light processing (DLP) and stereolithography apparatus (SLA).

If you’re in the market for a 3D printer, take time to become familiar with the basic categories. Also consider how you plan to use your printer and what you intend to produce. Some of these technologies are best suited to demanding industrial environments, while others are adaptable enough to accommodate the needs of small businesses and home hobbyists.